Manufacturing

Aerodyn are experts at precision machining, fabrications and assemblies

Aerodyn’s advanced manufacturing services provide high quality machining, fabrication, welding, and inspection services for all industries. We pride ourselves on being responsive and innovative, while maintaining the highest quality craftsmanship available.

-

Overview

-

Materials

-

CNC Turning Capabilities

-

CNC Milling Capabilities

-

EDM Capabilities

-

Welding and Manual Machining

Overview

We manufacture to both customer supplied drawings and drawings of our own design. By maintaining operations in-house, we control costs, quality, and schedule. The result is a reliable and timely delivery to meet our customers’ needs.

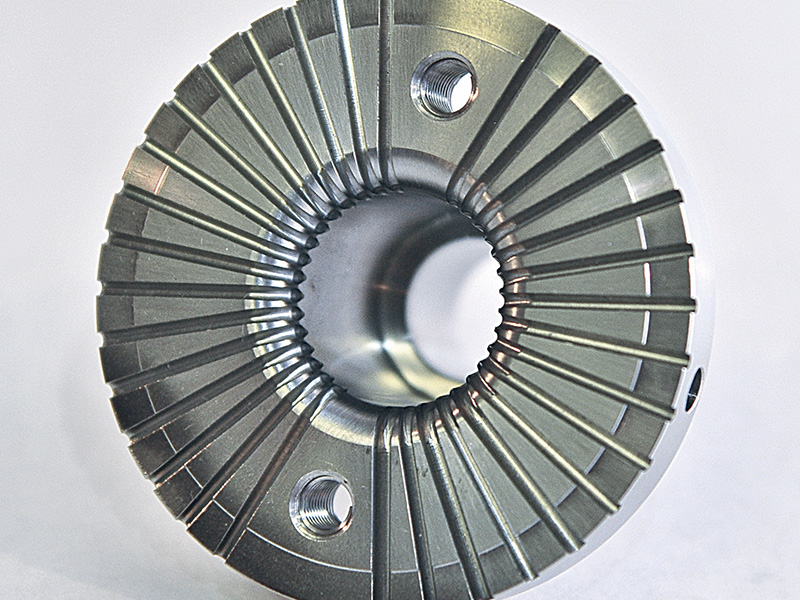

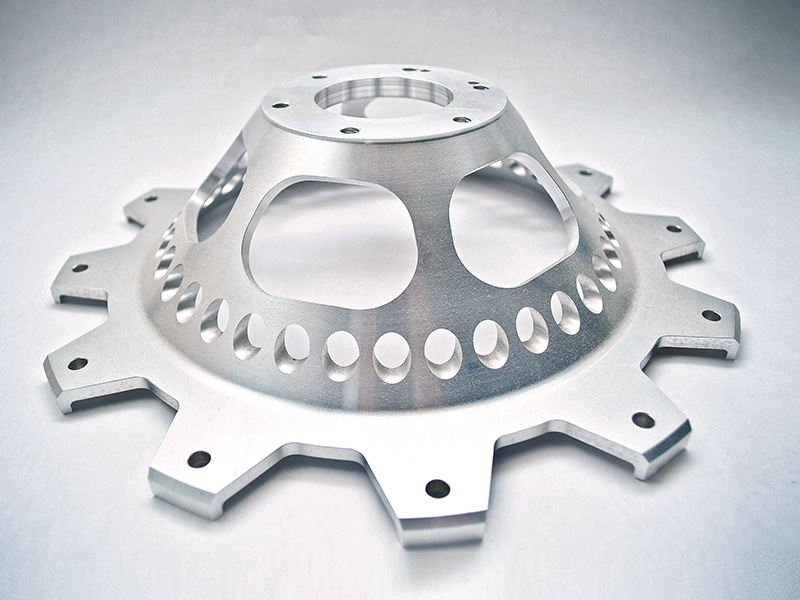

With our wide range of machining capabilities, we produce everything from the simplest of parts to extremely complex stationary and rotating engine hardware. We accept order quantities from one-off prototypes, to short-run and low-volume production.

Our in-house assembly capability allows us to provide our customers with a finished assembly that is ready for use upon delivery.

Materials

Aerodyn manufacture parts from a wide range of material types but specialize in difficult-to-machine nickel and cobalt alloys.

Common materials are:

- Inconel 600, 625, and 718

- Hastelloy X, Haynes 188, Haynes 25, Waspaloy

- Nimonic 75

- Platinum

- Titanium (several grades)

- Stainless steel (304, 316, 410, 440c, 15-5PH, 17-4PH)

- Alloys steels (4140, 4340)

- Carbon steels

- Aluminum (6061, 7075)

- Fiberglass, Plastics, and Ceramics

CNC Turning Capabilities

With turning capabilities ranging from ~.020” to 78” in diameter, Aerodyn can handle a very large range of part sizes and geometries.

Machine types and capabilities:

- Okuma V100R – A vertical turret lathe with max turning diameter of 48″ and max turning height of 35″. Live 3-axis tooling.

- Okuma LU400 – A horizontal 4-axis lathe with max turning diameter of 24″, distance between centers of 78.74″, chuck weight of 770lbs, and weight between centers of 1320 lbs.

- Okuma LU300 – A horizontal 4-axis lathe with max turning diameter of 14.57″ and distance between centers of 33″.

- Okuma LB3000 – Two horizontal multiple work centers with max turning diameter of 16.14″ and max turning length of 19.69″.

- Okuma LB2000 – A horizontal lathe with live tooling, bar feeder, max turning diameter of 16.93″, and max turning length of 11.81″.

CNC Milling Capabilities

With a wide range of milling capabilities, Aerodyn are set up to mill a vast array of hardware. We perform machining of everything from basic fixtures and tooling to engine cases and integrally bladed rotors.

Machine types and capabilities:

- DMG Mori DMU65 Monoblock – A vertical trunnion style 5-axis machining center with max work piece on rotary of 33″diameter x 20″height. Max work piece on rigid table of 39.4″x 33″x22″. The machining center includes an 18,000rpm spindle, high pressure through-spindle coolant, and on-machine probing.

- DMU 125 Monoblock – A vertical Trunnion style 5- Axis machining center with max work pieces on a rotary of 33” diameter and 20” height. The machining center includes an 30,000 rpm spindle, high pressure through spindle coolant, and on-machine probing. Machine includes (60) tool magazine.

- DMU 125 DuoBlock – A vertical Trunnion style 5- Axis machining center with max work pieces on a rotary of 49.2” diameter and 60” height. The machining center includes an 30,000 rpm spindle, high pressure through spindle coolant, and on-machine probing. Machine includes (120) tool magazine.

- Haas UMC 750 (Multiple) – A 5-axis universal machining center with max work piece of 19.7” dia x 20” height. Machine includes on machine probing and tool breakage sensors.

- Kitamura MyTrunnion 4X-T – A vertical trunnion “4+1” axis machining center with a max work piece of 23.62″diameter x 11.81″height. This machine utilizes a 15,000rpm spindle, 1000psi through-spindle coolant, and on-machine probing.

- Kitamura MyCenter 3XG (Multiple) – Two vertical 3-axis machining centers with removable 4th-axis rotaries (tailstock and trunnion table setups). Each machine has X-Y-Z travel of 30″x18″x18.1″, a 15,000rpm spindle, 1000psi through-spindle coolant, and on-machine probing.

- Mori Seiki NMV5000 – A vertical 5-axis machining center with max work piece of 27.6″diameter x 17.7″height, X-Y-Z travel of 28.7″x20.1″x 20.1″. Load capacity of 660lbs. This machine utilizes a 12,000rpm spindle, 1000psi through-spindle coolant, on-machine probing, and a manual pallet system.

- Mori Seiki NMV3000 – A vertical 5-axis machining center with a 30-pallet auto-pallet changer. This machine has a max work piece of 13.8″dia x 11.8″h, X-Y-Z travel of 19.7″x13.8″x20.1″. The load capacity on each pallet is 220lbs. This machine utilizes a 20,000rpm spindle, 1000psi through-spindle coolant, and on-machine probing.

- Okuma 1052– Vertical machining center with max work piece of 41.73” dia x 13.5” height on rigid table of 80.71 x 41.73. Machine includes on machine probing.

- Okuma GENOS M560-V (Multiple) – Two vertical 3-axis machining centers with a max work piece of 41.34” x 22.05” x 18.11” on a rigid table of 22.05” x 51.18”. Each machine has a spindle speed of 15,000 and on-machine probing.

EDM Capabilities

With a combination of plunge / ram EDM, wire EDM, and fast-hole EDM drilling available in the USA, Aerodyn have the capability to produce features that are extremely difficult, and many times impossible, via conventional machining methods.

Wire EDM:

- Mitsubishi MV2400ST – A CNC 4-axis wire EDM with max workpiece dimensions of 41.3″x32.3″x16.7″ and machining range of 23.6″x15.7″x16.7″.

- Mitsubishi MV4800-S Wire EDM – CNC advance tiype Wire EDM with max workpiece dimensions of 49.3” x 40.2” x 19.9” and machining range of 31.5” x 223.6” x 20.1”

Fast-Hole EDM Drilling:

- Belmont SY-1210 – A CNC 5-axis fast-hole EDM drill with X-Y-W-Z travels of 39.3″x47.2″x39.3″x15.7″. Tilt head +/- 100 degrees with 360˚ rotary. Work table 59″x 71″ with open top, so much larger workpieces have been done than travel range.

- Sodick Manual Hole Popper – A manual EDM drill with a 12″ Z-height. Open sides for acceptance of parts of all sizes.

Plunge / Ram EDM:

- Mitsubishi EA12V – A 4-axis CNC plunge EDM with a max workpiece size of 31.4″x21.6″x9.8″. Note: larger pieces can be burned above the tank using localized flushing.

- Mitsubishi EA12D – A 4-axis CNC plunge EDM with a max workpiece size of 39.3″x25.5″x13.7″. Note: larger pieces can be burned above the tank using localized flushing.

Welding and Manual Machining

Aerodyn carry multiple metal joining capabilities and have an assortment of support equipment to ensure we can meet our customers’ needs.

Welding and Metal Joining:

- TIG welding (AWS certified welders and weld inspectors on staff)

- MIG welding

- Laser welding

- Plasma cutting

- Torch brazing

- Soldering

Grinding:

- Mitsui surface grinder with Harig head

- Boyar Schultz surface grinder with Harig head

- Covel Surface grinder with Harig head

Manual Machining / Tool Room:

- Amada bandsaw with 16” diameter or 16”x16” cutting capacity

- Do-All Bandsaw

- Prototrak manual mill with CNC upgrade

- Chevalier “Bridgeport” style manual mill

- 2x manual tool room lathes

- Assortment of chop saws, bench grinders, and belt sanders

Speak with a Specialist

Get in touch with one of our experts in Design and Analysis, High Precision Manufacturing, Instrumentation, Assembly & Testing.