In-House Testing

Aerodyn have a test facility dedicated to offering global support of product development for hot air flow, vibration and spin testing

Aerodyn’s state of the art test facility features vast capabilities for new product development and testing to meet our customers’ needs. By coupling our extensive design, fabrication, and instrumentation capabilities, along with our LabVIEW certified engineers, Aerodyn offer the utmost support to allow for very quick test setups and delivery of results.

-

Vibration

-

Spin

-

Modal Analysis

-

Gas Stand

-

Aerodynamic Calibration

-

Abradable Coating

-

Airfoil Characterization

Vibration Testing

Aerodyn can provide a single source solution for your vibration testing needs. Our field testing expertise enables us to instrument your part, measure your component’s vibration environment, and perform the data reduction. We can design and fabricate the fixtures required for your vibration shaker test through our in-house CAD, analysis, and fabrication services. Based on the measured application data, we can develop the appropriate vibration input profile and test your part. Vibration testing can also be conducted to customer supplied specifications. Vibration shaker testing can be performed on our three electrodynamic shakers equipped with slip tables.

Types of vibration shaker testing we can perform:

- Sinusoidal

- Random

- Sine on random

- Random on random

- Resonance search and dwell

- Classical shock

- Shock response spectrum

- Combined temp/vibe exposure

- Resonance search and dwell

Typical applications include:

- MIL-STD-810

- RTCA/DO-160

- Blade characterization

- Testing application of strain gages to critical strain areas

- Exciting blades at the modes to determine strain ratios of max strain to engine gages

- Blade fatigue testing

- Cold or hot (induction heating)

- Modal testing

- Rotating vibration testing

- Combined hot gas and vibration environment with airflow up to 5kb/sec and 900°C

Equipment:

- Tira 20,000 lbf shaker with slip table

- ETS 15,400 lbf shaker

- Thermotron 6000 lbf shaker with slip table

- Wilcoxon Research D125 piezoelectric shaker

- Aerodyn designed piezoelectric shaker for frequency range 2,000hz to 20,000 hz

- VR controllers

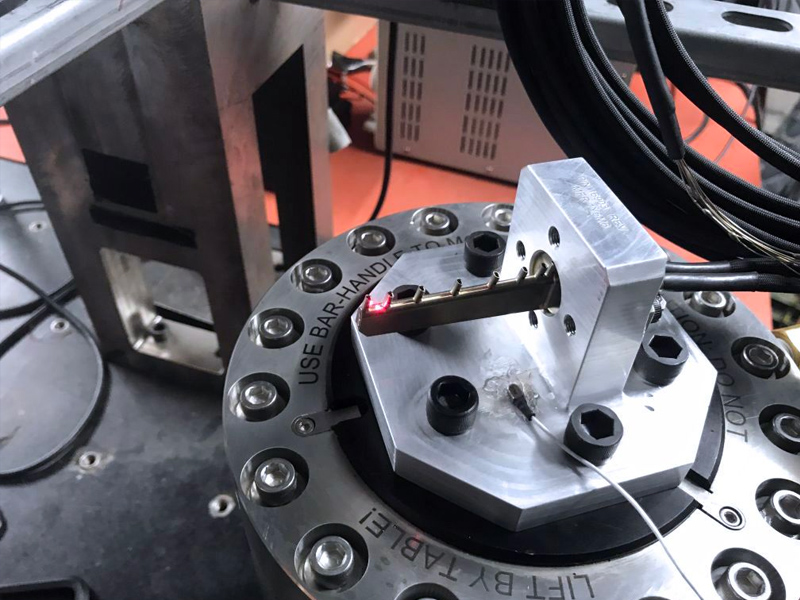

Spin Testing

Aerodyn has multiple spin rig facilities (both in the US and in the UK) designed to perform a variety of spin tests on sensors and test components in the development process. We can test at high G loads and temperatures. Additionally, we can utilize our inventory of slip rings to gather rotating data during testing, or to provide power to telemetry or other active sensors.

Modal Analysis & Testing

Aerodyn perform modal analysis using ME’scope™ software to determine a component’s structural resonances. Forces are applied to test articles with a variety of excitation methods, including impact hammers and portable shakers. Measurements of operating deflection shapes (ODS) can be animated, an extremely valuable tool in understanding a component’s vibratory responses to input forces.

We offer:

- Data acquired from hardware of all sizes and complexity

- Animated and graphical representation of frequency mode shapes

- Verification of a component’s structural response to design modifications such as bracket re-design

- Correlation of analytical models to experimental results

- Portable systems for on-site testing

Gas Stand Testing

- Mass flows to 7 kg/s (15 lbm/s) continuous on-site

- Up to 900°C

- 8 Gas stands

- Turbocharger compressor/ turbine mapping

- Centrifugal compressor performance mapping

- Heavily instrumented tests

- Burst containment tests

- LCF cycling

- Thermal and pressure cycling

- Pressure testing

- Leakage/Flow testing

- 900 gallon per minute fluid flow capability

- 200 ton heat rejection capability

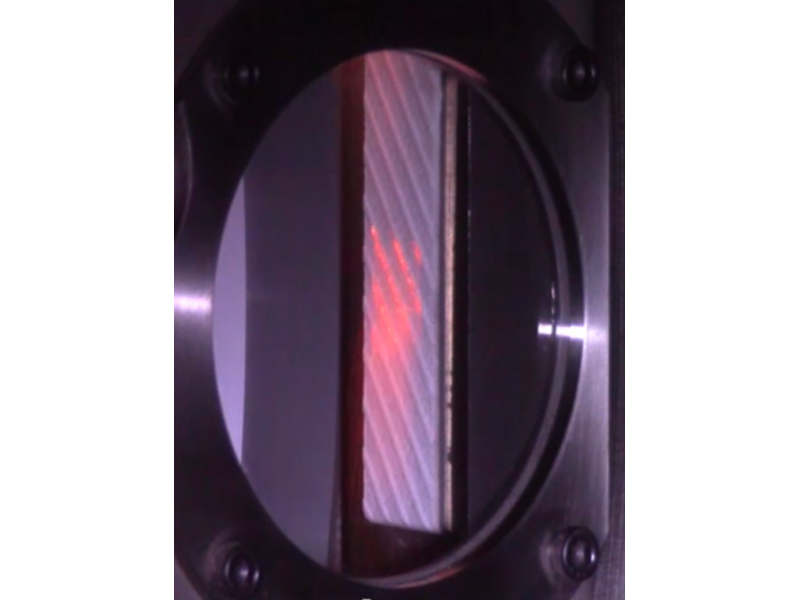

Aerodynamic Calibration

Aerodyn offer flow calibration of rakes and probes via our flow tunnel. Yaw and pitch can be varied to sub-degree increments, while temperature and pressure measurements are taken, stored, and reduced to data files and plots. This information is often vital and necessary to correctly use the rake or probe. The maximum yaw and pitch capability depends on the rake geometry. Varying nozzle diameters can produce air speeds up to .95 Mn.

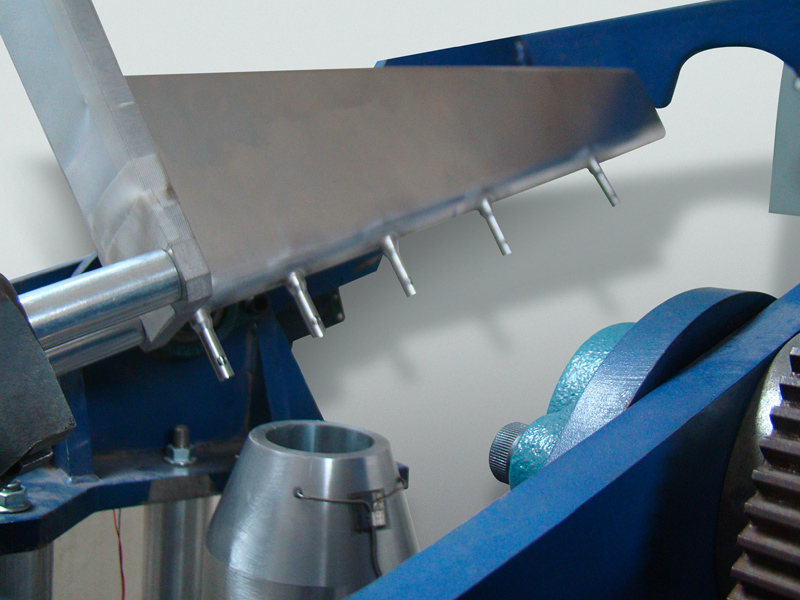

Abradable Coating Testing

Aerodyn have created a test rig designed to test the performance of abradable coatings.

- Impact velocities up to 410 m/s

- Temperatures up to 1600°C

- Incursion rates between 1 and 2000 μm s−1

Triaxial force measurements record force during rub, along with pyrometer for temperatures.

Optical scanning and CMM measurement perform post-test analysis of the data.

Airfoil Characterization

Aerodyn conduct airfoil analysis by means of Stress Ratio testing. Accurate determination of stress levels and locations are made by analyzing signals from an array of strain gages placed at critical locations. Vibratory modes are excited using electro-dynamic, piezoelectric, acoustical, and air siren equipment.

We can provide:

- Dynamic strain measurements at numerous locations over a frequency range of 10 Hz to 25 kHz

- Correlation of predicted stress locations for individual modes using Ansys™ and GageMap™

- Strain amplitude ratios relative to reference gages provided for all frequency modes of interest

- Correlation of tip deflection to maximum strain for response modes

- High cycle fatigue testing (HCF) providing strain levels and tip deflections of airfoils to failure

Speak with a Specialist

Get in touch with one of our experts in Design and Analysis, High Precision Manufacturing, Instrumentation, Assembly & Testing.